News

-

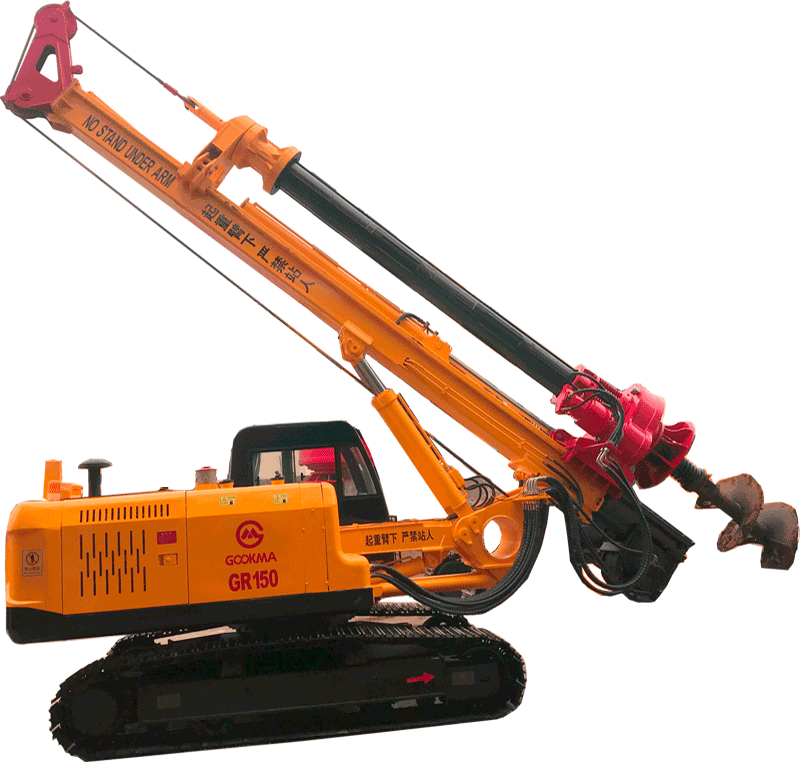

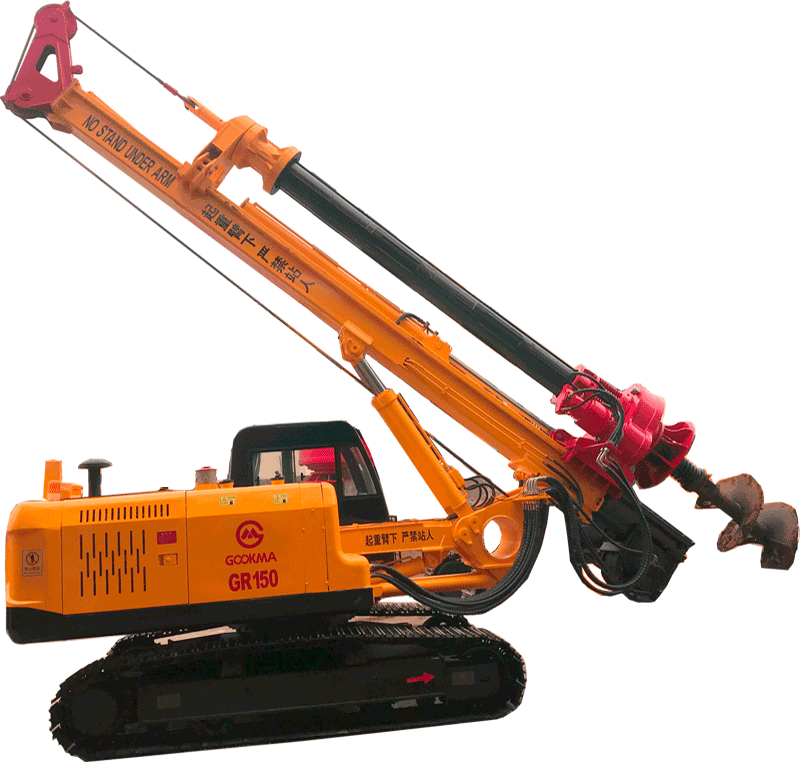

Method of Rock Crushing for a Rotary Drilling Rig

1. Construction overview of rotary drilling rig A rotary drilling rig is a piling machine used for drilling holes in construction foundation engineering. It has the advantages of fast construction speed, good hole quality, small environmental pollution, flexible and convenient operation, high saf...Read more -

How to Choose a Rotary Drilling Rig

What kind of rotary drilling rig is good? Firstly, let’s take a look at the advantages of rotary drilling rig construction. Advantages of rotary drilling rig construction: 1. The entire rig was placed on an automatically walking urban belt chassis. Strong mobility, fast displacement. Stro...Read more -

Reasons of Abnormal Fuel Consumption of the Piling Machine

Piling machine also calls rotary drilling rig. Piling machine has many advantages such as small size, light weight, simple operation, convenient in construction, and relatively low cost etc. But if the piling machine failure or improper operation, it will lead to abnormal oil consumption. &nbs...Read more -

Sizes and Compositions of Concrete Mixer

Sizes of Concrete Mixer truck Small concrete mixer are around 3-8 square meters. The larger ones range from 12 to 15 square meters. Generally the concrete mixer trucks used in the market are 12 square meters. Concrete mixer truck specifications are 3 cubic meters, 3.5 cubic meters, 4 cubic meters...Read more -

Why Did the Rotary Drilling Rig Tip Over?

The mast of the rotary drilling rig is generally more than ten meters or even tens of meters long. If the operation is slightly improper, it is easy to cause the center of gravity to lose control and roll over. The following are the 7 reasons for the rollover accident of the rotary drilling rig:...Read more -

Engine Is Not the Only Important Part of a Rotary Drilling Rig

Engine is the main power source of a rotary drilling rig in various industries such as oil and gas exploration, geothermal drilling, and mineral exploration. These engines are usually large and powerful because they must generate enough torque and horsepower to drive the rig’s rotary...Read more -

Reasons for Excessive Excavator Engine Noise

As a heavy mechanical equipment, the noise problem of excavators has always been one of the hot issues in their use compared to other mechanical equipment. Especially if the engine noise of the excavator is too loud, it will not only affect the working efficiency of the excavator, but also distu...Read more -

How to Deal with Oil Seepage of Horizontal Directional Drilling Rig?

Relief valve oil seepage of HDD machine Oil seepage at the bottom of the relief valve: Replace the seal ring and remove the connecting bolt. Oil seepage at the rear of the relief valve: tighten the bolts with an Allen wrench. Solenoid valve oil seepage Valve bottom seal is damaged: Replace the...Read more -

Application Areas of Rotary Drilling Rig and Selection of Drill Bit

Rotary drilling rig, also known as piling rig, is a comprehensive drilling rig which can be used for a wide range of substrates with fast hole making speed, less pollution and high mobility. The short auger bit can be used for dry digging, and the rotary bit can also be used for wet digging with ...Read more -

How to Choose an Excavator Extension Arm Wisely?

The excavator extension arm is a set of excavator front working devices specially designed and manufactured according to the working conditions to expand the working range of the excavator. The connection part must strictly conform to the connection size of the original excavator, so as to facil...Read more -

Construction Technology of Horizontal Directional Drilling Rig (II)

1.Pipe pullback Measures to prevent pullback failure: (1) Perform visual inspection of all drilling tools before horizontal directional drilling work, and perform flaw detection inspection (Y-ray or X-ray inspection, etc.) on major drilling tools such as drill pipes, reamers, and transfer boxes t...Read more -

Construction Technology of Horizontal Directional Drilling Rig (I)

1.Guide construction Avoid curve deviation and the formation of “S” shape in guided construction. In the construction process of directional drilling through, whether the guide hole is smooth or not, whether it is consistent with the original design curve, and avoid the appearance o...Read more