I. Introduction of no-dig technology

No-dig technology is a kind of construction technology for laying, maintenance, replacing or detecting of underground pipelines and cables by method of less digging or no digging. The no-dig construction uses the principle of directional drilling technology, greatly reduces the affection of underground pipeline construction to the traffic, environment, infrastructure and living and working of the residents, it becomes an important part in current city for technical construction and management.

The trenchless construction was started from 1890s and was grown up and became an industry in 1980s in developed countries. It has been developing very fast in the past 20 years, and currently was widely applied in many pipe laying and maintenance construction projects in many industries such as petrol, natural gas, water supply, power supply, telecommunication and heat supply etc.

Gookma Technology Industry Company Limited is a hi-tech enterprise and a leading manufacturer of horizontal directional drilling machine in China.

You are welcome to contact Gookma for further inquiry!

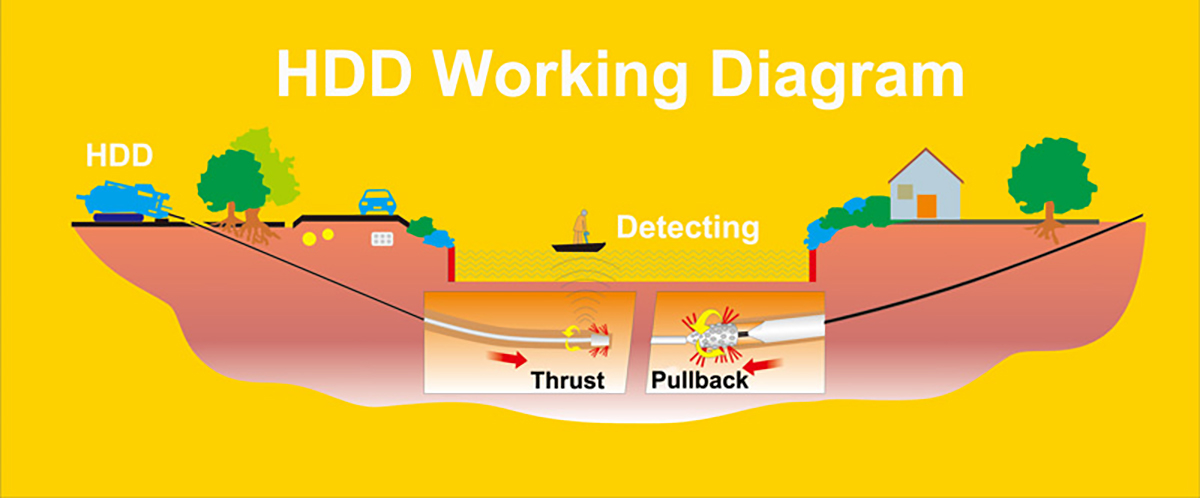

II. Working Principle and Steps of Construction of Horizontal Directional Drill

1.Thrusting of the drill bit and drill rod

After fixing of the machine, according to the set angle, the drill bit drives the drill rod rotating and forward by the force of power head, and thrust according to the required depth and length of the project, cross the obstacles then come to the ground surface, under the control of the locator. During thrusting, in order to prevent the drill rod from clamping and locking by the soil layer, it must to made swelling cement or bentonite by the mud pump through drill rod and drill bit, and the while to solidify the passageway and prevent the hole from caving in.

2. Reaming with the reamer

After the drill bit leads the drill rod out of the ground surface, remove the drill bit and connect the reamer to the drill rod and fix it, pullback the power head, the drill rod leads the reamer move backward, and expand the size of the hole. According to the pipe diameter and diversity, changing different size of reamer and ream once or more times until reaching the required hole diameter.

3. Pullback the pipe

When reaching the required hole diameter and the reamer is going to be pulled back the last time, fix the pipe to the reamer, the power head will pull the drill rod and brings the reamer and the pipe to move backward, until the pipe was pulled out to ground surface, the pipe laying works are completed.

Post time: Mar-15-2022